Welcome to Zhishang Steel Co., Ltd.

TEL: (Gavin) +86-15665898999 | Email : info@zhishangsteel.com

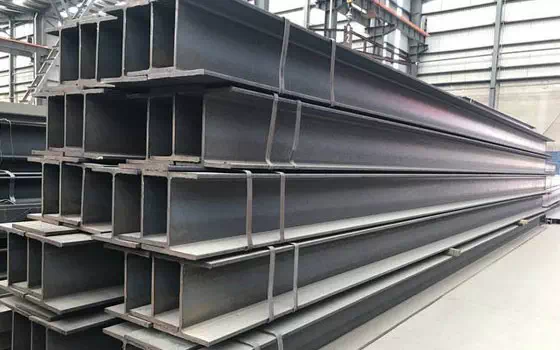

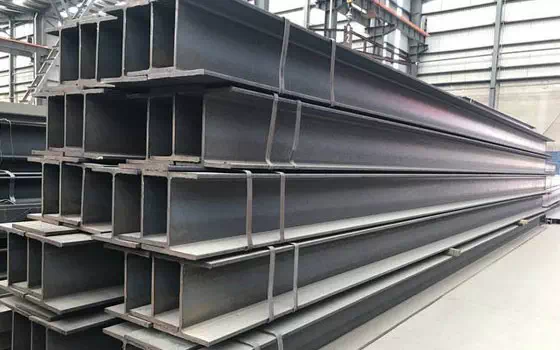

Generally, before the use of I-steel, we are exposed to the air for a long time, but once the time is too long, the I-steel has a great chance of chemical reaction with oxygen and moisture in the air, resulting in rust affecting the efficiency of use. So in order to prevent this phenomenon, the following is a small series for you to do a detailed introduction:

1. It shall not be stacked together with acid, alkali, salt, cement and other materials that are corrosive to I-steel in the warehouse. Different specifications of I-beams should be stacked separately to prevent confusion and prevent contact corrosion.

2. I-steel should pay attention to prevent rain or mixed impurities before storage, and the I-steel that has been rained or soiled should be wiped by different methods according to its nature, such as the available steel wire brush with high hardness, cloth and cotton with low hardness.

3. The site or warehouse for the storage of I-steel should be selected in a clean and unobstructed place, away from factories and mines that produce harmful gases or dust. The field should be cleared of weeds and all debris, keep the steel clean.

The three commonly used cutting methods of I-steel are:

1. Plasma cutting, its cutting speed is fast, and it is special for the cutting of non-ferrous metals. The cutting process will produce a lot of smoke and dust, and with its fast cutting function and plasma beveling function, it is also widely used in the market.

2. Laser cutting, high precision thermal processing, but low efficiency, high cost, only a few large enterprises and high-precision cutting field can be used.

3. Flame cutting, suitable for cutting 5-300mm carbon steel plate material, its cutting thickness is large, high efficiency, cutting no groove, simple to use, the raw materials used for cutting mainly oxygen and cutting gas, low cutting cost, is a more practical and common cutting type.

Zhishang Steel has always been a pioneer in custom steel and special supplies, and has been recognized for its efforts in enhancing work efficiency and product quality. In addition to ISO9001:2015 certification, we also adhere to strict quality policies and proprietary procedures. If you have any questions, please contact us to provide the best type of product solution for your pre-painted, coil coating metal process, we will closely support after-sales service to ensure that your subsequent problems can be solved in a timely manner, if you have any questions, please send email to info@zhishangsteel.com, we look forward to serving you.

Zhishang Steel, specializing in domestic steel products trade, warehousing, processing and other services. The team has four service teams: Shandong Zhishang Steel Co., LTD., Shandong Zhiyiheng Trading Co., LTD., Tai 'an Zhishang Economic and Trade Co., LTD., Shandong Zhishang Steel Structure Co., LTD. Mainly engaged in steel coil, coated, stee···