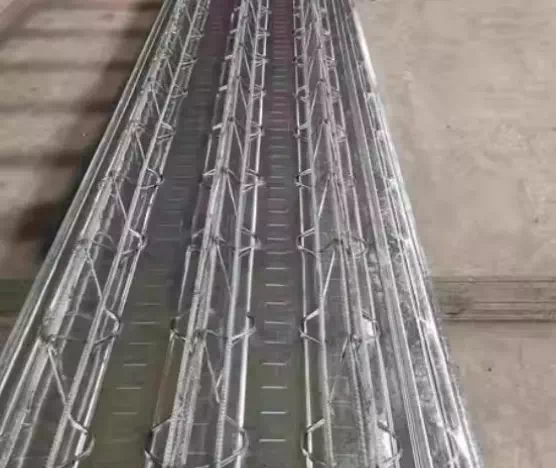

Heavy-duty reinforced steel truss floor deck steel bearing plate

Heavy-duty reinforced steel truss floor deck steel bearing plate. This special steel bearing plate bears a considerable portion of the weight and load of the entire building structure and is one of the key elements to ensure the overall stability and safety of the building.

Product selling points

* This is one of our most popular styles at the moment.

* We offer multiple styles for you to choose from.

* This model is one of our top recommendations.

Description

Heavy-duty reinforced steel truss floor deck steel bearing plate. This special steel bearing plate bears a considerable portion of the weight and load of the entire building structure and is one of the key elements to ensure the overall stability and safety of the building.

It is widely used in places with extremely high requirements for structural strength and load-bearing capacity, such as high-rise buildings, large factories, and Bridges. In these complex architectural environments, heavy-duty steel truss floor deck steel bearing plates play an indispensable role, just like the "backbone" of the building, supporting various structures and facilities above and bearing tremendous pressure from all sides.

Judging from its structure, it is made of high-strength steel through meticulous design and precise processing. Steel itself possesses excellent mechanical properties and is capable of withstanding tremendous tensile, compressive and shear forces. The structural design of the steel bar truss further enhances its load-bearing capacity and stability. This unique structural form enables the steel bearing plate to evenly disperse stress when subjected to force, avoiding local stress concentration, thereby significantly enhancing the reliability and durability of the entire component.

In practical applications, the installation of heavy-duty steel truss floor deck steel bearing plates must be carried out strictly in accordance with relevant norms and standards. Professional construction teams will use advanced hoisting equipment and technology to accurately place it in the predetermined position and firmly connect it with other components. Each connection point has been carefully treated and reinforced to ensure the integrity and stability of the entire structure.

In addition, to meet different construction requirements and environmental conditions, this type of steel bearing plate can also be customized and produced according to specific circumstances. For instance, in some places with high requirements for fire prevention and anti-corrosion, special fire prevention and anti-corrosion treatments will be carried out to extend their service life. In some areas that need to bear special loads, their structures will be further optimized and strengthened to meet the actual engineering requirements.

Parameter

Product | Galvanized steel truss floor deck for construction projects, self-bearing floor deck for steel trusses, processed reinforced truss floor slabs |

Materials | Q195,Q235,Q345; ASTM A53 GrA,GrB; STKM11,ST37,ST52,16Mn。 |

Thickness | 0.1 millimeters -25 millimeters |

Width | 100mm - 2500mm or as per your requirements |

Length | 5m-14m, 5.8m, 6m, 10m-12m, 12m or as per the actual requirements of the customer |

Standard | BS4449-2005,GB1449.2-2007,JIS G3112-2004,ASTM A615-A615M-04a, |

Grade | Grade A, Grade B, Grade C |

Cross-sectional shape | Spiral shape, herringbone shape, crescent shape |

Technology | Steel bars and iron rods |

Packaging | Bundle, or with PVC of various colors or as per your requirements |

Surface treatment | 1.Galvanizing |

Certificate | API ISO9001-2008,SGS.BV |

Advantages

Good mechanical properties: Steel bar trusses provide rigid support, which can reduce the use of temporary supports and can withstand large loads. They are suitable for large-span (3-12m) buildings with heavy loads, such as factories, shopping malls, and warehouses.

High construction efficiency: It can significantly reduce the on-site steel bar binding volume (by 60% - 70%), increase the construction speed, and also meet the requirements of rapid construction of the main steel structure. It can provide a stable working platform in a short time and can adopt the flow construction of laying floor deck slabs on multiple floors and pouring concrete slabs layer by layer.

Environmental protection and energy conservation: By adopting the prefabrication method, it can significantly save construction time and labor costs. During the usage stage, the floor deck serves as the tensile reinforcement for the concrete floor slab, enhancing the rigidity of the floor slab and reducing the consumption of steel bars and concrete.

Key points of construction

Preparations before construction

Technical preparation: Be familiar with construction drawings, understand the design intent and the construction norms and technical standards to be referred to; Conduct technical briefings and pre-job technical training for all operating workers; Prepare the construction organization design in accordance with the requirements of the design documents and construction drawings, and draw up a detailed project schedule.

Material acceptance: Check whether the model of each part of the steel bar truss floor deck is consistent with the drawings, inspect the factory certificate of conformity, and verify whether the appearance quality of the steel bar truss floor deck upon entry, the structural dimensions of the steel bar truss, and the appearance quality of the welding between the steel bar truss and the bottom formwork meet the relevant standard requirements.

On-site condition preparation: This includes rechecking the welding quality and elevation of steel beams, inspecting the embedded parts of shear walls, etc. At the same time, safety passages and protective nets should be set up, and safety and technical briefings for the operation personnel should be completed.

Installation process

Preparations before lifting: Place the reference line for laying the steel truss floor deck on the beam, confirm the completion of the shear wall formwork and steel bar works, prepare simple operation tools, such as soft slings and components for hoisting, labor protection supplies for the operators, etc., provide technical and safety briefings to the operators, and issue operation instructions.

Floor deck lifting: Use on-site tower cranes for loading materials, and adopt belt slings. It is strictly prohibited to directly bind and lift with steel wire ropes to avoid deformation. When lifting, each bundle should be fixed with two steel wire ropes at one quarter of the length of the steel plate at both ends. A test lift should be conducted first to check if the center of gravity is stable and if the soft slings will slide. Only when it is safe and without any concerns can the lifting be carried out.

Floor deck laying: Before laying, mark the reference line for laying the deck according to the starting position shown on the drawing. Align the first deck with the reference line and install the other decks in sequence. The joints between the decks should be tight to ensure no leakage of concrete during pouring. Pay attention to the consistent direction of the laying. The length of the steel truss extending into the upper flange of the steel beam must meet the design requirements. The resting length of the truss plate on the flange of the steel beam should not be less than the larger of 5d (d is the diameter of the lower chord steel of the truss) and 50mm. A 20mm distance should be left at the junction of the two slabs on the upper flange of the beam to facilitate the operation when laying the slabs.

Non-standard plate end: At the end of the span, if the width of the truss plate is less than 600mm, non-standard plates can be used for laying. The non-standard plates should be arranged according to the spacing of the truss reinforcement. If the width of the non-standard plate is less than 180mm, reinforcement with the same diameter as the lower chord reinforcement of the truss should be used for laying.

Welding of plate support ribs to steel beams: Ensure a firm connection.

Check the leakage areas: Deal with any possible leakage problems in a timely manner.

Arrange the distribution bars and additional bars: Arrange them in accordance with the design requirements.

Subsequent construction: After the installation of the floor deck is completed, subsequent construction steps such as stud welding, edge formwork installation, node treatment, and concrete pouring will be carried out. Finally, a quality inspection will be conducted.

Quality advantage

* All products go through strict quality inspections before leaving the factory.

* I’m confident you’ll be satisfied with the sample quality once received.

* We only use 100% brand-new raw materials.

Online Message

Hot Products

News Center

- The King of Colored Elastomers - High-performance Copper-based Alloy Beryllium Bronze 2026-02-05

- Overview of Steel Structures 2025-12-08

- A Comprehensive Analysis of Stainless Steel Applications: A Study on Its All-round Utilization from Traditional Industries to Cutting-edge Technologies Introduction (2) 2025-11-21

- A Comprehensive Analysis of Stainless Steel Applications: A Study on Its All-round Utilization from Traditional Industries to Cutting-edge Technologies Introduction (1) 2025-11-21

- Introduction to Stainless Steel Angle Steel Structure and Identification Methods 2025-11-20

- The application scenarios of floor deck slabs are extensive 2025-08-18

- Iron Bone and Thin: The Five-High Mystery of China's Carbon Steel Thin Plates and the Way to Break Through the Wall 2025-07-07

- The types of floor slabs and the mainstream models 2025-06-26

- Comprehensive Analysis of ASTM 301 / JIS SUS301 Stainless Steel 2025-05-21

- Is stainless steel safe ? 2025-05-15

Zhishang Steel Co., Ltd

Zhishang Steel, specializing in domestic steel products trade, warehousing, processing and other services. The team has four service teams: Shandong Zhishang Steel Co., LTD., Shandong Zhiyiheng Trading Co., LTD., Tai 'an Zhishang Economic and Trade Co., LTD., Shandong Zhishang Steel Structure Co., LTD. Mainly engaged in steel coil, coated, stee···