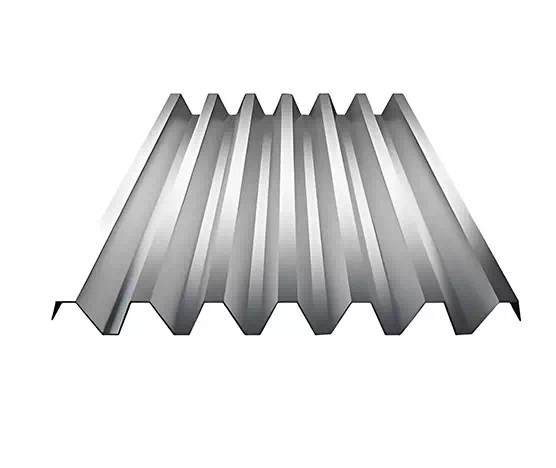

New type of galvanized open web floor slab reinforced concrete load-bearing slab floor deck

Galvanized floor deck slabs are mainly composed of galvanized open-web slabs and reinforced concrete. Galvanized open-web plates usually adopt Q235B or Q345B hot-rolled steel plates. After galvanizing treatment, they have good anti-corrosion performance.

Product selling points

* This is one of our most popular styles at the moment.

* We offer multiple styles for you to choose from.

* This model is one of our top recommendations.

Description

Galvanized floor deck slabs are mainly composed of galvanized open-web slabs and reinforced concrete. Galvanized open-web plates usually adopt Q235B or Q345B hot-rolled steel plates. After galvanizing treatment, they have good anti-corrosion performance. In terms of thickness, open floor deck slabs are generally 0.8-1.2mm, and closed floor deck slabs are 0.9-1.5mm. The common widths are 600-1200mm (for open floor deck slabs) and 500-1000mm (for closed floor deck slabs). The reinforced concrete part is composed of steel bars and concrete. The steel bars generally include upper chord steel bars, lower chord steel bars, web bar steel bars, etc. The strength grade of the concrete is determined according to the specific design requirements.

Parameter

Product name | Galvanized floor deck | |||

Category | Galvanized steel | |||

Basic materials | Hot-dip galvanized steel (Z)/ Aluminum-zinc coated steel (AZ)/ Zinc-aluminum-magnesium coated steel (AM)/ Zinc-magnesium (ZM) | |||

Weight of zinc coating | 40g/m ²-275g/m ² | |||

Zinc coating type | Regular brightening/minimized brightening/no brightening | |||

Size | Width: 600mm-1500mm/ Thickness: 0.3mm - 4mm (Customizable size) | |||

Surface treatment | Hot-dip galvanizing/customized | |||

Colour | White, blue, red, grey, custom colors | |||

Application | Architecture, automobiles, electrical appliances, electrical equipment, etc. | |||

Corrosion resistance | Excellent | |||

Weather resistance | Suitable for outdoor use | |||

Processing service | Welding, stamping, cutting, bending, uncoiling, forming | |||

Yield strength | Q195/Q235/Q355/SD345/S350GD/S550GD/SGH440/Q355B | |||

Tolerance | +5% | |||

Grade | DX51D/DX52D/DX53D/TDC51D/TDC52D/TDC53D/SGCC/CGCC/ZM/TS350GD/TS550GD | |||

Advantages

Superior mechanical properties

High strength: It can withstand considerable pressure and tensile force, providing reliable support for steel structure buildings and ensuring the stability of the building structure. When working in conjunction with concrete, it can fully leverage the tensile strength of steel and the compressive strength of concrete, thereby enhancing the overall load-bearing capacity.

High rigidity: It can effectively reduce the deformation of the floor slab, ensure the flatness of the floor, and provide good conditions for subsequent decoration and use.

Convenient construction

Save formwork: There is no need to build a large number of temporary formworks, reducing the usage of formwork and the workload of assembly and dismantling, and accelerating the construction progress.

Easy installation: The profiles of floor deck plates are usually thin and relatively light in weight, which is convenient for transportation and installation. The flow construction method of laying profiled steel sheets on multiple floors and pouring concrete slabs layer by layer can be adopted to improve the construction efficiency.

Good economy:

Material cost: To a certain extent, it reduces the overall cost of building materials. Although galvanized steel plates have a certain cost, considering factors such as construction efficiency and reduction of formwork costs comprehensively, they have good economic performance.

Easy to update: If the building needs to be renovated or updated, the galvanized corrugated floor deck is easy to remove and replace, reducing the cost of maintenance and renovation.

Other advantages:

Easy to industrially produce: It can be mass-produced through standardized production processes to ensure the consistency of product quality and specifications, meeting the needs of different construction projects.

Strong bonding force: The surface embossing of the profiled sheet creates the maximum bonding force between the floor deck and the concrete, making the two form an integral whole. Coupled with stiffening ribs, the floor deck system has a high load-bearing capacity.

Strong corrosion resistance: The galvanized layer can effectively prevent steel plates from rusting and corroding, extending the service life of floor deck plates. It is especially suitable for some building environments with high durability requirements.

Product classification and specifications

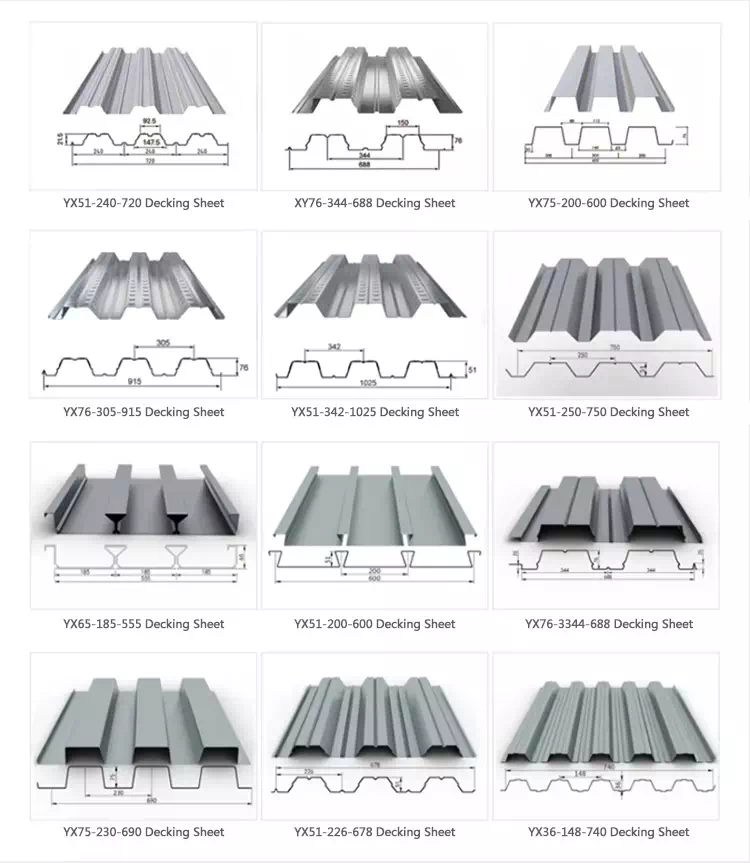

Classification: Common types include open floor deck slabs, closed floor deck slabs and constricted floor deck slabs, etc. Different types of floor deck slabs vary in performance, applicable scenarios and appearance. Users can make their choices based on specific engineering requirements.

Specification: Diverse models Common specifications include YXB65-170-510, YXB-60-180-540, YXB65-185-555, YXB48-200-600, YXB66-240-720, and YXB40-185 740, YXB60-263-790, YX75-200-600, YX70-200-600, YX76-344-688, YX75-230-690, YX51-240-720, YX35-125 750, YX51-250-750, YX51-305-915, YX76-305-915, YX51-342-1025, YX51-200-600 (s), YX51-190-760 (s), etc. The thickness of the floor deck plate profiles is generally 0.8mm, 1.0mm, 1.2mm, the width is 688mm - 940mm, and the height is 51mm - 76mm.

Construction requirements

The thickness of the galvanized coating: The profiled steel sheet used for the floor deck should be galvanized steel sheet, and the thickness of the galvanized coating should also meet the requirement that it will not rust or be damaged during the service life.

The width of the trough: The average width of the trough for pouring concrete should not be less than 50mm. When stud connectors are set in the groove, the total height of the combined floor slab should not exceed 80mm.

The thickness of the floor slab: The thickness of the composite slab should not be less than 90mm. The thickness of the concrete above the top surface of the profiled steel sheet should not be less than 50mm.

Anchor requirements: Anchor bolts should be set at the ends of the composite panels. The studs should be set at the concave ribs of the profiled steel sheet at the end support, penetrate the profiled steel sheet and weld both the studs and the steel sheet firmly to the steel beam.

Support length: The support length of the profiled steel sheet in the composite plate on the steel beam should not be less than 50mm. The support length on the masonry should not be less than 75mm.

Usage method

Laying and connection: The floor deck is laid and connected to the steel beam. The end of the deck is spot-welded to the steel beam through penetration, and the middle part is spot-welded to the steel beam through penetration using stud bolts. The floor deck slabs are connected by clamping and pressing holes with special clamping pliers. The plugs are spot-welded with special galvanized plug plates to the floor deck plates and steel beams.

Special circumstances handling:

Cantilever slab: Under cantilever conditions, the floor deck slab only serves as a permanent formwork. The length of the cantilever can be determined according to the cross-sectional characteristics of the floor deck. To prevent the cracking of the cantilevered panels, negative bars should be provided at the supports as designed by the structural engineer.

Floor elevation change: When the floor structure elevation changes inuniformly, measures such as adding welded steel sections should be taken to make the horizontal structure transition in steps. When the elevation is reduced, Angle steel is welded to the web of the I-beam. When raising the elevation, channel steel is welded to the flange of the I-beam.

Reserved openings: When there are reserved openings on the floor, if the size is generally larger than 500mm×500mm, the measure of opening the opening first is adopted, that is, welding steel beam supports on the steel beam for separation to increase the rigidity of the opening. The mesh reinforcement is disconnected at the opening and welded to the steel beam. When the opening size is less than 500mm×500mm, the post-opening measure is adopted, that is, adding a blocking division plate on the floor deck, the mesh steel bars are connected, and the steel bars can be cut after the concrete is poured and formed.

Quality advantage

* All products go through strict quality inspections before leaving the factory.

* I’m confident you’ll be satisfied with the sample quality once received.

* We only use 100% brand-new raw materials.

Online Message

Hot Products

News Center

- The King of Colored Elastomers - High-performance Copper-based Alloy Beryllium Bronze 2026-02-05

- Overview of Steel Structures 2025-12-08

- A Comprehensive Analysis of Stainless Steel Applications: A Study on Its All-round Utilization from Traditional Industries to Cutting-edge Technologies Introduction (2) 2025-11-21

- A Comprehensive Analysis of Stainless Steel Applications: A Study on Its All-round Utilization from Traditional Industries to Cutting-edge Technologies Introduction (1) 2025-11-21

- Introduction to Stainless Steel Angle Steel Structure and Identification Methods 2025-11-20

- The application scenarios of floor deck slabs are extensive 2025-08-18

- Iron Bone and Thin: The Five-High Mystery of China's Carbon Steel Thin Plates and the Way to Break Through the Wall 2025-07-07

- The types of floor slabs and the mainstream models 2025-06-26

- Comprehensive Analysis of ASTM 301 / JIS SUS301 Stainless Steel 2025-05-21

- Is stainless steel safe ? 2025-05-15

Zhishang Steel Co., Ltd

Zhishang Steel, specializing in domestic steel products trade, warehousing, processing and other services. The team has four service teams: Shandong Zhishang Steel Co., LTD., Shandong Zhiyiheng Trading Co., LTD., Tai 'an Zhishang Economic and Trade Co., LTD., Shandong Zhishang Steel Structure Co., LTD. Mainly engaged in steel coil, coated, stee···