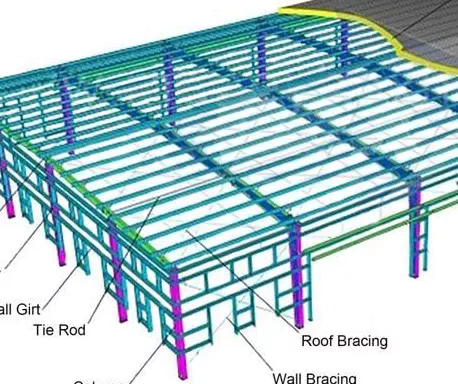

High strength galvanized Q235H light steel structure construction booth

I Beam, also known as steel beam (English name Universal Beam), is a section of the I-shaped strip of steel. I - beams are divided into ordinary I - beams and light I - beams. It is a section steel with an I-shape.

Product selling points

* This is one of our most popular styles at the moment.

* We offer multiple styles for you to choose from.

* This model is one of our top recommendations.

〣Description

I Beam, also known as steel beam (English name Universal Beam), is a section of the I-shaped strip of steel. I - beams are divided into ordinary I - beams and light I - beams. It is a section steel with an I-shape

I - steel is mainly divided into ordinary I - steel, light - duty I - steel and wide flange I - steel. According to the height ratio of flange and web, it can be divided into wide, medium and narrow wide flange I-beams. The specifications of the first two are 10-60, that is, the corresponding height is 10-60 cm. At the same height, the light I - beam flange is narrow, the web is thin, the weight is light. Wide flanged I-beams, also known as H-beams, are characterized by parallel legs and no inclination inside the legs. It belongs to the economic section steel, is rolled on the four-high universal mill, so it is also called "universal I-steel". Ordinary I - beams, light - duty I - beams have formed national standards.

Whether the I-section steel is ordinary or light, because the section size is relatively high and narrow, the moment of inertia of the two main axes of the section is large, so it can only be directly used in the web plane bending members or it is composed of lattice stressed members. On the axial compression member or perpendicular to the web plane and bending members are not suitable, which makes it in the application range has a great limitation. I - beams are widely used in buildings and other metal structures. Ordinary I-beam, light I-beam, because the section size are relatively high and narrow, so the moment of inertia of the two main axes of the section is relatively different, which makes it in the application range has a great limitation. The use of I-beam should be selected according to the requirements of the design drawings. The selection of I-steel in the structural design should be based on its mechanical properties, chemical properties, weldable properties, structural size and other reasonable selection of I-steel

〣Vantage

1.COST-EFFICIENCY:Faster design/build process / Lowered labor costs / Reduced maintenance costs

2.DURABILITY:Steel is resistant to many of the typical threats experienced by wood, such as rot, mold, mildew, pests and fire.

3.CLEAR SPAN-ABILITY:The less structural obstructions required for your building the more square footage you can put to work for your company's bottom line.

4.FLEXIBLE DESIGN OPTIONS: Your warehouse can also be designed to incorporate a mix of clear span spaces and traditional office spaces or living spaces.

5.ECO-FRIENDLY:Cool metal roofs / Vapor barriers / Vapor barriers / Solar panels

〣parameter

〣Packing&Delivery

The steel materials shall be packed carefully for full protection. Specifically, main structure materials are generally loaded into 40'OT shipping containers, while sky light, ventilators, roof panels, wall panels and other accessories are loaded into 40'HC shipping containers for delivery.

〣Our service

3D model.

3D building information modeling software used in the building and construction industries for steel and concrete detailing, we make this model for customer to create and manage 3D structural models in concrete or steel, and guides them through the process from concept to fabrication.

Foundation plan.

We provide foundation plan for your project for free. Please just make local geological report

If you need, we would love to send the anchor bolts and mold. Before the production work finish, you can do the foundation work first.

Building installation drawing.

Free installation drawing for your project. To make the erection work more clear and easier.

Besides, we make each steel component with different mark, only refer to the drawing and pick the right one to build.

〣FAQ

1.Are you a manufacture or trading company?

Reply: We have the right to import and export business in China , is a comprehensive and large-scale industry and trade enterprises. You are welcomed to visit us for inspection at any time .

2.What are the main products your company produces?

Reply: The business scope of my company is mainly structural steel construction, such as industrial workshop, light steel mobile house, container house, warehouse, high-rise frame office building and frame structure of large equipment, etc. In addition, we also provide steel structure processing service, like the processing of H- steel, steel beam ,steel beam ,color steel plate, C-Purlin steel, Z-Purlin steel , floor deck etc.

3.What's the quality grade of the steel structure components?

Reply:Q345B is used for main steel structure, Q235B is used for secondary steel structure.

4.How about the derust grade?

Reply:Ball blasting Sa2.5 on main steel structure manual derust St2.0 on secondary steel structure.

5.How to install it?

Reply: We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step.We also could send the engineer your local to help you if needed.

6.Maintenance:

Reply:Finish paint need to be done after the frame installed,and do it again after 6-8 months in order to keep the surface for a long life time.

Quality advantage

* All products go through strict quality inspections before leaving the factory.

* I’m confident you’ll be satisfied with the sample quality once received.

* We only use 100% brand-new raw materials.

Online Message

Hot Products

News Center

- The King of Colored Elastomers - High-performance Copper-based Alloy Beryllium Bronze 2026-02-05

- Overview of Steel Structures 2025-12-08

- A Comprehensive Analysis of Stainless Steel Applications: A Study on Its All-round Utilization from Traditional Industries to Cutting-edge Technologies Introduction (2) 2025-11-21

- A Comprehensive Analysis of Stainless Steel Applications: A Study on Its All-round Utilization from Traditional Industries to Cutting-edge Technologies Introduction (1) 2025-11-21

- Introduction to Stainless Steel Angle Steel Structure and Identification Methods 2025-11-20

- The application scenarios of floor deck slabs are extensive 2025-08-18

- Iron Bone and Thin: The Five-High Mystery of China's Carbon Steel Thin Plates and the Way to Break Through the Wall 2025-07-07

- The types of floor slabs and the mainstream models 2025-06-26

- Comprehensive Analysis of ASTM 301 / JIS SUS301 Stainless Steel 2025-05-21

- Is stainless steel safe ? 2025-05-15

Zhishang Steel Co., Ltd

Zhishang Steel, specializing in domestic steel products trade, warehousing, processing and other services. The team has four service teams: Shandong Zhishang Steel Co., LTD., Shandong Zhiyiheng Trading Co., LTD., Tai 'an Zhishang Economic and Trade Co., LTD., Shandong Zhishang Steel Structure Co., LTD. Mainly engaged in steel coil, coated, stee···